AUTO-TRIM LOCKING TUNING MACHINES

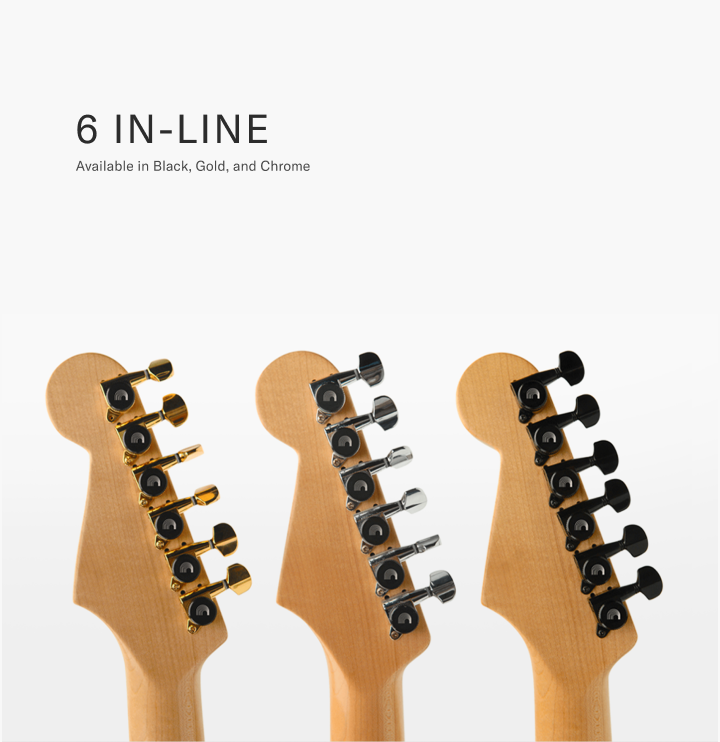

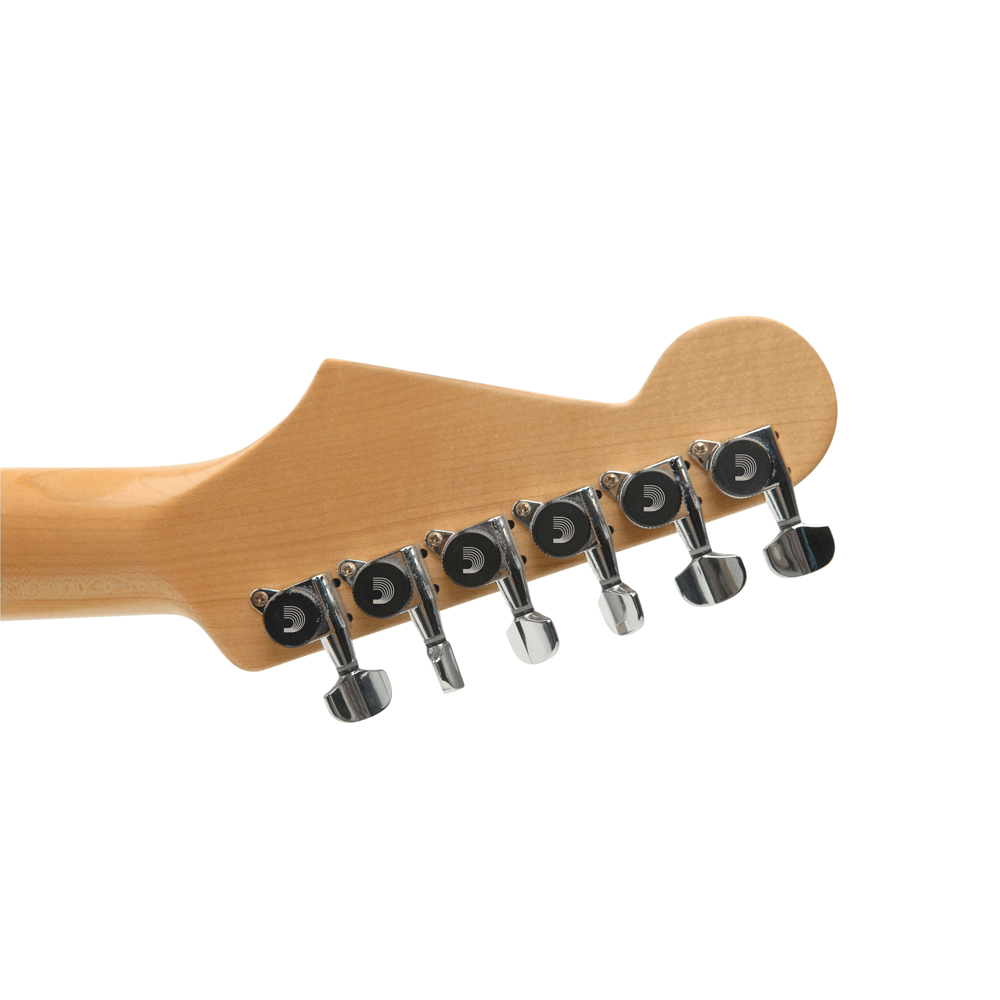

6 In-line, Chrome PWAT-6R1

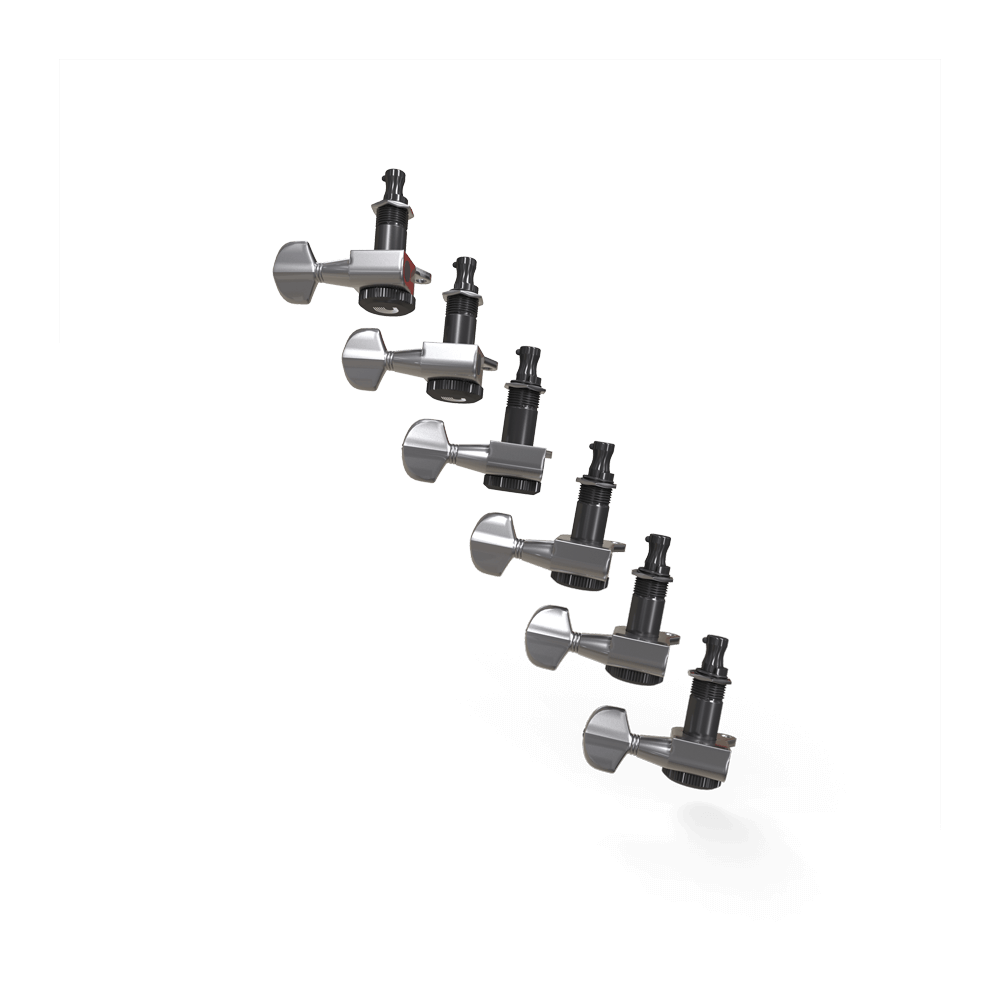

The D'Addario Auto-Trim Locking Tuning Machines are precision tuners that eliminate the need for multiple windings and automatically cut off the excess string during string changes. This eliminates the need for string clippers making string changes easy and fast. Simply insert sting, tighten clamp, and tune to pitch. The 18:1 ratio worm gear constructions ensures greater precision than standard tuners and ensure tuning stability even during the hardest playing. Includes 6 tuners and mounting hardware.

your selection is currently unavailable

$99.99

Or

15,300 PTS

Code Value:

1,700 Points

Additional Details

Product Features

Product Specs

String Tension Chart

Additional Resources